Homes progress. Households add an induction range or a heat pump. Somebody buys an EV. A backyard workshop grows from a hobby to a small business. Then the lights dim when the clothes dryer kicks on, or a breaker journeys each time the area heating unit and the microwave run together. All of these stories meet at the exact same point: the electrical panel. Understanding when to update, why it matters, and how to do it well can avoid nuisance journeys, safeguard devices, and eliminate threats that are difficult to see until something goes wrong.

What an electrical panel in fact does

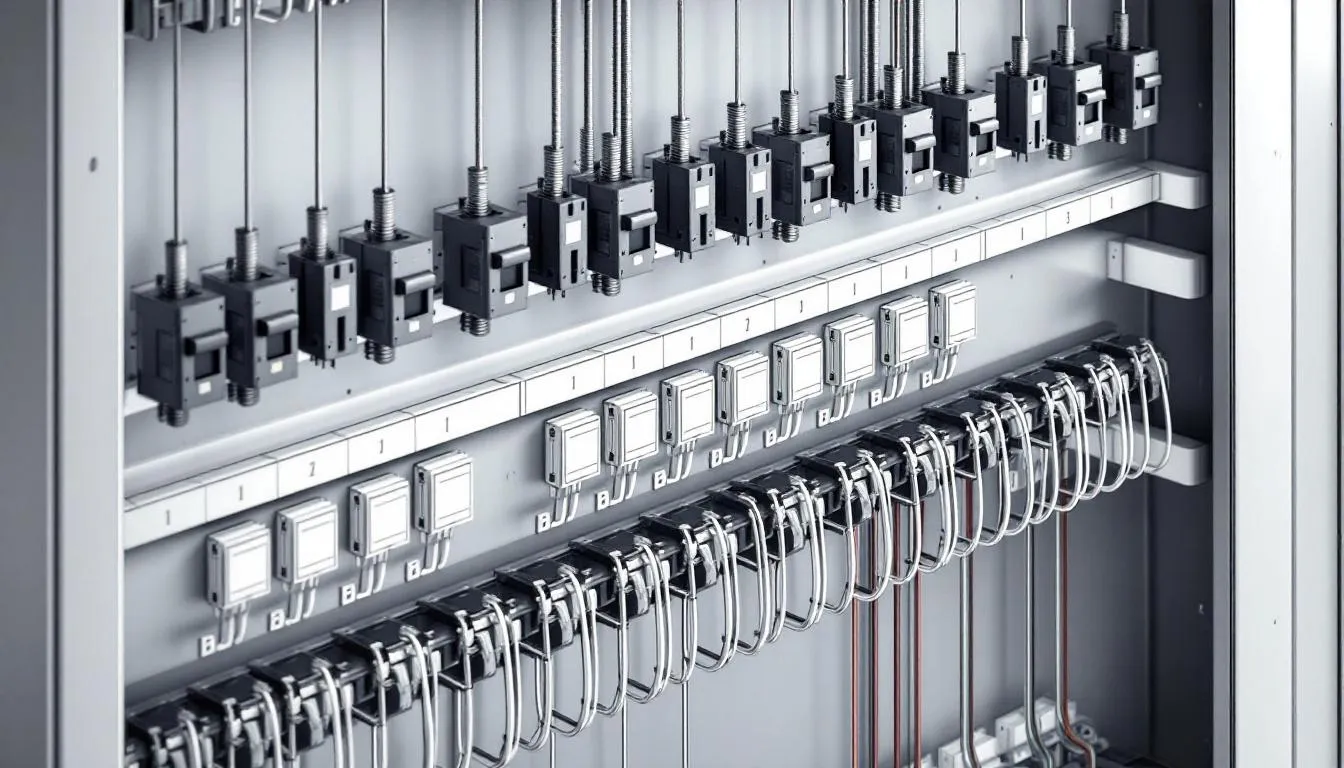

The electrical panel is the circulation brain of a building. Power from the energy or a main detach arrive on bus bars inside the cabinet. Individual circuits branch off through breakers sized for the wire they safeguard. The panel's task is not simply convenience. It is a security device. Breakers trip under overloads and short circuits to safeguard wiring insulation from overheating. The neutral and ground bars terminate return paths and bonding. The enclosure itself is noted to contain faults and heat.

Two numbers control panel conversations. The service size in amperes explains the score of the entire system, normally 60, 100, 125, 150, 200, or 400 amps for homes. Then there is the panelboard score which should be equal to or greater than the service. Numerous crowning achievement 100 or 200 amp services. For modern-day loads like EV charging, electric heat, medspas, and accessory residence units, 200 amp service is quick ending up being the baseline.

The peaceful signals that your panel is due for replacement

Most individuals think an upgrade just matters when the lights flicker or breakers constantly journey. Those are apparent informs, but the quiet indicators are just as essential. I have opened panels where the door looked neat, yet inside the neutrals shared terminals, or aluminum branch conductors had drifted loose. The devices itself, not just the signs, drives the decision.

Consider these common triggers for a panel upgrade:

- Repeated tripping that associates with normal usage, especially when 2 or 3 high-draw devices perform at once. An existing 60 or 100 amp service in an all-electric or soon-to-be all-electric home, consisting of heat pump, induction cooktop, or EV charging. Obsolete or recalled panel brands and breaker types known for failure to trip, getting too hot, or poor bus connections. Evidence of overheating like blemished insulation, brittle breakers that wiggle on the bus, or a musty burnt odor when the cover is removed. Remodeling that includes square video, a rental suite, or major fixed-in-place appliances such as a sauna or a shop-grade air compressor.

I have had homeowners ask whether a single nuisance journey means the panel is bad. Normally not. A single journey can be a toaster, a vacuum beginning existing, or a tool with a frustrating inrush. Repeated trips with a pattern inform the story. If the vacuum journeys the same bed room breaker each time, odds are the circuit is overwhelmed with area heating units or entertainment gear, not that the electrical panel failed. An excellent evaluation differentiates circuit-level issues from systemic limits.

The special cases that are worthy of extra attention

There are understood issue panels, and they stick around because they frequently keep working right up till they do not. Federal Pacific Electric Stab-Lok breakers have a long history of stopping working to trip reliably under overload. Particular Zinsco and Sylvania panels struggle with bus corrosion and bad clip stress. I still see these in 1960s and 1970s homes. If you have one, replacement belongs on your list, even if you have actually not noticed problems yet. Insurance providers are progressively cautious of them, and buyers frequently negotiate replacement during a sale.

Another diplomatic immunity is any panel revealing aluminum branch circuits from the 1960s to early 1970s. Aluminum feeders are common and typically great Article source when terminations are rated and preserved. Branch circuits on older aluminum, specifically ended under gadgets not noted for AL conductors, can loosen up in time. A panel upgrade alone will not fix branch wiring, however it is a natural moment to remedy terminations, add approved connectors, or prepare a rewiring strategy.

Finally, take a look at homes that grew organically without a plan. Numerous subpanels inserted into closets. Laundry rooms that became small electrical spaces. Romex getting in through knockouts without bushings. Panels embeded in restrooms or other prohibited areas. These are code and security problems initially, capacity issues second.

Load calculation, not guesswork

Upgrading on inklings can result in spending too much or undersizing. The best path starts with a load calculation. Electrical experts utilize a demand-based method consistent with the National Electrical Code, applying demand aspects to basic lighting loads, small device circuits, fixed home appliances, A/C, and EV charging. A real-world example shows why this matters.

Say a 1,900 square foot home has gas heat and water, but plans to add a 48 amp EV charger, an induction range, and a mini-split for the garage. Existing service is 100 amps. A fast back-of-envelope might suggest 200 amps. A proper calc might show that the real varied load with the brand-new devices lands around 120 to 140 amps at optimal need. That still supports a 200 amp upgrade but frames the electrical panel margin correctly. It likewise guides breaker sizing and wire runs for the EV charger.

Conversely, consider an all-electric home with a 9 kW heat pump, a 10 kW backup heat strip, a 50 amp variety, a 30 amp clothes dryer, and 2 EV battery chargers that might run simultaneously on weekend nights. Even with demand aspects, these loads point toward either load management or a 320 amp (typically called 400 amp class) service with double meter positions. The computation assists decide in between higher service versus wise sharing.

Why upgrading improves more than capacity

Capacity gets the attention, however a modern electrical panel upgrade enhances several less apparent aspects.

- Arc and ground fault defense broadens. New breakers offer combination AFCI and GFCI in more configurations. Kitchens, laundry locations, and indoor living spaces take advantage of improved protection against parallel arcs and ground faults that old panels could not address. Fault existing ratings and temperature level efficiency enhance. Old bus designs and breaker footprints have restrictions that contemporary listed assemblies fixed. Better fault rankings suggest enhanced durability if a tool or cable shorts. System organization and future-proofing get simpler. A larger cabinet with more spaces prevents tandem breakers packed into constraints. Clean labeling and devoted home-run circuits decrease fixing later. Neutral and grounding arrangements become code-compliant. In service equipment, neutrals bond to the enclosure and grounds. In subpanels, they must be separated. Numerous tradition setups get this incorrect. Upgrades fix that, in addition to correct grounding electrode connections and bonding jumpers. Compatibility with energy systems boosts. If you plan solar, battery storage, or load-shedding gear, a contemporary main panel with an offered bus ranking and space for a generation meter or a feeder tap is the foundation.

Common challenges that alter scope and cost

People often request for a single number. The truth is that panel upgrades vary from uncomplicated to complicated. A basic swap in an available garage, with adequate service conductor slack and a cooperative utility, can be a one-day task. The license, inspection, and coordination are still vital, but the manual labor is clear. Other jobs grow due to the fact that of covert constraints.

Meter-main combos versus interior panels matter. In regions where the service detach must be outside, upgrading a meter-main can activate stucco patching, channel reroutes, and even energy mast replacement. Service conductors might be undersized, or the mast does not have the height clearance above a roof. As soon as opened, deterioration on the service lugs may force further replacement up to the weatherhead.

Inter-system bonding terminations frequently do not exist on older homes. Modern rules need bonding points for communication and low-voltage systems. Including them is easy, but it is another line item.

Clearance and working space can force relocation. Panels require a minimum working depth and width, and certain rooms are off-limits. I have actually been contacted us to "replace a panel" mounted inside a clothes closet. The best fix was to transfer to the garage back-to-back, spot the closet wall, and extend circuits. That is a various project than a like-for-like swap.

On older masonry or lath-and-plaster walls, attaching a new bigger cabinet typically reveals that the wall can not accept basic anchors without collapsing. Plywood backer boards and mindful framing repairs may be needed. Anticipate an electrician who flags this before the day of setup to be the one who finishes on time.

The permit and energy dance

An electrical panel upgrade is not just a contractor in a truck. You will require an authorization. In most jurisdictions, a service upgrade activates an evaluation by the authority having jurisdiction and a coordination consultation with the utility to disconnect and reconnect power. Scheduling can include days. Experienced electricians anticipate the sequence: pre-approval of the riser diagram, assessment the exact same day as the work, and an energy reconnect window in the afternoon.

For overhead services, the energy's duties and your electrician's obligations fulfill at the weatherhead or service point. For underground services, the demarcation may be at the handhole or meter base. Sometimes, the utility requires a brand-new meter base or a various meter place. The earlier this is sorted out, the smaller the surprise.

If your upgrade includes a jump in amperage, the utility might assess transformer capacity and service drop size. Periodically, the neighborhood transformer can not support numerous upgrades without a modification. That does not imply you can not proceed, but it does affect timeline and may involve an expense share depending upon the energy's policies.

What a good upgrade day looks like

I recommend property owners to prepare for a full day without power. Charge phones, empty the ice maker, and think about a cooler for the refrigerator contents. The crew should get here with a comprehensive circuit map, or they make one as they open the existing panel. Circuits get tagged, conductors pulled back, and the old cabinet eliminated. The new cabinet mounts plumb and level, with cable television entries dressed through listed connectors, bushings set up where required, and conductors landed by circuit with appropriate torque.

Bonding and grounding get unique attention. If the home lacks 2 ground rods, the electrical contractor drives them and bonds them with constant wire. If there is a metal water service, the bond jumper gets installed within the required range of the entry point. In a split system with a removed garage or subpanels, the neutral remains separated at those downstream panels. That is among the most common errors in DIY or handyman work.

Breakers are sized to the wire, not to the device nameplate desire list. If a range circuit uses 8 AWG copper, the breaker matches the conductor, even if the home appliance claims a larger breaker is acceptable. New AFCI and GFCI breakers go in where code requires them or where the house owner selects greater protection. The labeling is clear and particular. "Kitchen little devices west counter" beats "cooking area." A tidy panel today saves hours later.

The inspector looks at labeling, conductor terminations, working clearances, service devices bonding, grounding electrodes, and utility-side compliance. As soon as signed off, the energy reconnects. Great crews can move quickly without cutting corners. The distinction is preparation.

Safety upgrades that ride along with a panel replacement

A panel modification is the best moment to remove a couple of persistent threats:

- Replace all breakers that serve bed rooms or living areas with mix AFCI models, even if your local amendments allow older setups. It catches parallel arcs and cord damage that standard breakers will not. Add GFCI protection for outdoor, garage, bathroom, and cooking area counter top circuits, preferably in the breaker so downstream outlets stay safeguarded even if gadgets are changed later. Evaluate any multi-wire branch circuits. If they share a neutral, they need a 2-pole common trip breaker or noted manage ties. That guarantees the neutral is never loaded while one hot is off and the other is on, a condition that can overheat the neutral. Confirm rise protection. A Type 2 whole-home surge protective device at the panel is affordable compared to the cost of electronics and contemporary appliances. Clean up neutrals and premises. Each neutral should land under its own terminal. Premises can be bundled as enabled by the bar's listing. This prevents a nasty class of intermittent faults.

When a subpanel is smarter than a bigger service

Sometimes the primary panel is full, but the service is appropriate. If you are not including big continuous loads, a subpanel is a low-impact service. For example, a garage workshop gets a little 60 amp subpanel fed from a 2-pole breaker in the primary panel. You get spaces where you need them, minimize cable clutter, and avoid the energy coordination. The secret is to preserve separated neutrals in the subpanel and make sure the feeder consists of separate neutral and ground conductors sized to the load.

Load management technology has actually also grown. Numerous EV chargers and water heaters use load sharing or need reaction. A 50 amp breaker can serve 2 chargers that communicate, each throttling to prevent exceeding the circuit's ranking. For homes where a service upgrade is cost-prohibitive due to utility requirements, clever load controllers can make the existing electrical panel work safely while you prepare for a future service change.

Budget varieties and what drives them

Numbers vary by area, however useful ranges help set expectations. A like-for-like 100 amp to 100 amp panel replacement in an accessible place may range from 1,500 to 3,000 dollars, consisting of authorization and assessment. A 100 to 200 amp service upgrade with a new panel, meter base, grounding updates, and utility coordination often lands between 3,500 and 6,500 dollars. Complex outside meter-main upgrades, mast work, wall repair work, and moving can press into the 7,000 to 12,000 dollar zone. Add solar-ready provisions, surge defense, and higher-end breakers, and the total moves accordingly.

The most inexpensive bid is not always the very best worth. Products matter. An electrical contractor who uses noted fittings for every cable television entry, torques every lug to specification, and labels every circuit will conserve you time and potential failures later on. If a rate looks too excellent, ask what it consists of: authorization costs, AFCI/GFCI breakers where needed, brand-new grounding electrodes, new meter base if needed, conduit replacement, stucco or drywall patching, and rise protection.

How to prepare your home and your schedule

A little preparation makes upgrade day easier for everyone. Clear a four-foot radius in front of the panel. If the panel beings in a laundry room, relocation appliances aside. Eliminate kept items from racks near the office. If family pets get worried by noise or open doors, provide a quiet space. If the team needs access to the attic to trace or reroute circuits, make the hatch available and caution about insulation depth.

Expect a power-down window. The majority of crews aim to end up and restore power the exact same day, but delays can take place if the utility window slips or surprises emerge behind the panel. I suggest a battery light, a charged power bank, and planning meals that do not require significant cooking during that window. If you depend on medical devices, let your electrician know well in advance so they can schedule accordingly.

Real examples from the field

A house owner called about flickering LED can lights when the dryer started. The panel was a late 1980s model, 100 amp, tidy on the outside. Inside, the neutral bar was jam-packed two or 3 conductors deep per terminal, and several neutrals shared terminals with grounds. The bus revealed pitting around 2 breaker positions, probably from a loose breaker clip and arcing. The service calculation with planned loads, consisting of a 40 amp EV charger, pressed beyond a safe margin. We updated to a 200 amp panel, remedied neutrals, included a whole-home surge protector, and moved lighting to devoted arcs with AFCI defense. The flicker disappeared, and more notably, the loose terminations that were preparing the bar were gone.

Another job included an artisan cottage with a pantry panel that violated clearance and location guidelines. The property owner wanted an induction variety and a heatpump water heater. We transferred the panel to the basement stair wall with correct working area, set up a new meter-main outside, and fed a subpanel upstairs for kitchen area circuits to keep run lengths sensible. The inspector flagged the missing inter-system bonding, which we added. The utility needed a mast replacement due to clearance over the roofing. Because we addressed it early, the schedule still held.

Not every home needs a 200 amp upgrade. A little condominium with gas heat and hot water heater had a full 100 amp panel, tandem breakers everywhere, and frequent journeys in the office. We installed a 60 amp subpanel in a closet adjacent to the primary panel location, moved the office circuits and the cooking area little home appliance circuits to the subpanel, and replaced key breakers with dual-function AFCI/GFCI designs. No energy participation and a portion of the cost.

What to ask your electrician

Credentials and self-confidence are obvious, however ask targeted questions. Do they plan to perform an official load computation? Will they update grounding electrodes as needed? How will they manage AFCI and GFCI requirements? Do they include a rise protector? Will they identify circuits specifically and supply a panel directory that matches the as-built layout? How do they collaborate with the energy, and what is the anticipated failure window? If you are considering solar or batteries, inquire about bus score, main breaker size, and any scheduled arrangements for a generation meter or a feeder tap.

If proposals vary considerably, compare scope line by line. One bid may consist of a brand-new meter base and mast, while another assumes recycling marginal equipment. One might count on tandem breakers, another on full-sized areas. The information reveal why rates diverge.

When urgency matters

There are times when you do not wait. Any indication of overheating at the electrical panel, such as a melted breaker, sweltered bus bar, or that apparent electrical burning smell, should have immediate attention. Federal Pacific or Zinsco equipment with visible corrosion, fragile breaker manages, or regular unexplained trips need to be assessed without delay. Water invasion from a leaking meter enclosure or overhead mast can track down into the panel, oxidizing connections and producing surprise resistance locations. If you see rust tracks, staining, or white powdery residue around connections, call an expert. Short-term measures like de-energizing particular circuits might be suitable till replacement.

Looking ahead: capability, convenience, and resilience

Homes are adding load. Heatpump are taking over for gas heating systems. EVs are not fringe any longer. Even without going all-electric, the large variety of electronic devices means our circulation panels carry more responsibility than panels from 1975 ever imagined. A thoughtful upgrade does not simply bump amperage. It brings your electrical system into positioning with current safety standards, arranges circuits for much easier living, and sets the stage for renewables, storage, or future remodels.

The best results come from a measured approach. Verify the existing condition of the electrical panel, determine any brand name or age-related threat, calculate real demand with your prepared changes, and select a course that appreciates both your budget plan and your future strategies. Hire somebody who deals with torque specs and labeling as seriously as conductor size. The expense of doing it best is concrete. So is the cost of cutting corners.

A home with a tidy, well-labeled, appropriately sized electrical panel feels various to reside in. The microwave no longer dims the lights. The garage battery charger runs overnight without tripping. The breaker directory site in fact assists when you require to turn off the hot water heater. And when a storm rolls through, that rise protective device you included silently takes the hit rather of your refrigerator and router. That is what an upgrade buys you: security, capability, and a system you can trust.